Furnishing Rollers

- 13 November 2024

- Posted by: Scott Pendlebury

- Category: ITR Laser Engraving

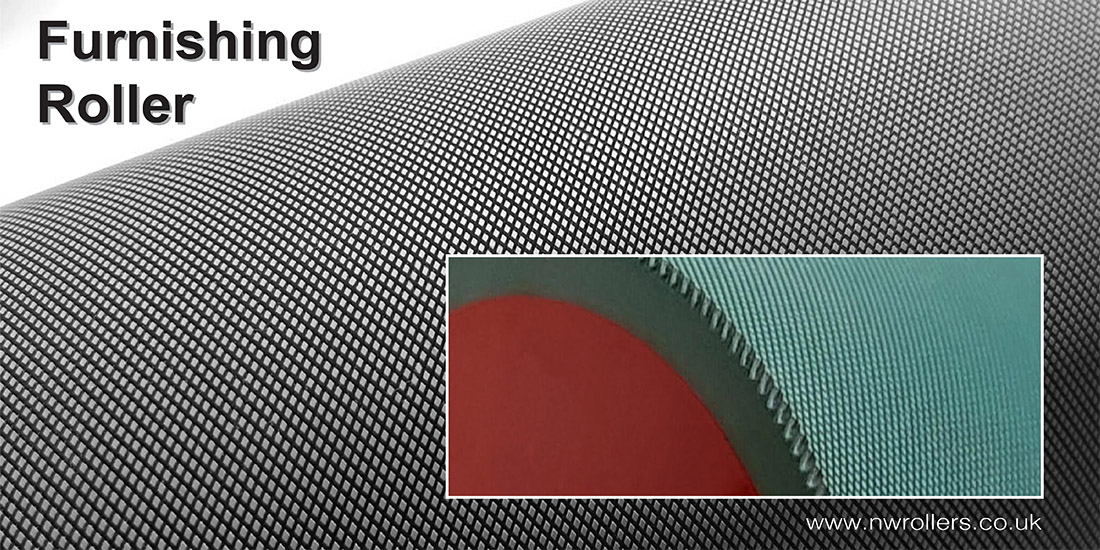

Furnishing rollers can be used for many different printing applications. They’re essential tools for feeding printing ink along a roller engraved with a pattern or design.

The surface areas of the furnishing rollers are engraved via ITR laser engraving, a high-precision process that ensures consistent and accurate engraving. The rollers consist of a fine holding cell or line structure TPI (threads per inch), which allows for an even coating with the correct and exact density, resulting in high-quality print output.

NW Rollers, with over 30 years of experience, has a long-established, highly regarded reputation in manufacturing furnishing rollers in the UK. Our expertise and commitment to quality make us a trusted choice for your printing needs.

Furnishing Rollers: The Process

The roller manufacturing process is a testament to our commitment to precision and quality. Each of the following steps is taken to ensure that each roller meets the most demanding of standards and needs:

- Precision engineering of aluminium cores

- ITR laser engraving of printing rollers is computer-controlled

- Industry-leading adhesives for durable bonding

- Digital balancing to remove the risk of roller vibrations. The balancing allows rollers to rotate smoothly for longer and at high speeds without servicing.

- Anodising rollers for surface protection

- Grinding and turning on CNC machining centres—these are computerised, numerically controlled machines using pre-programmed software to enhance precision manufacturing. This means our rollers are more dimensionally accurate with superior concentricity, resulting in superior lamination and print quality.

Lastly, we conduct final quality control checks and measurements to ensure that all our rollers meet our high standards. Our rollers are designed to give outstanding ink transfer, even to the smallest cells, ensuring superior print quality.

Longevity

We understand the importance of maintaining roller equipment, so we also provide expert furnishing roller refurbishment services for used rubber-covered printing presses and laminator rollers.

Why Choose Our Rollers?

NW Rollers are laser-focused on continuous high standards and quality output. We have the UK’s largest engraving facility and 30+ years of experience manufacturing high-definition flexographic sleeves.

Throughout our manufacturing process, we offer:

- Our rollers are made from top-of-the-range materials sourced from leading suppliers around the world. These include adhesives, coatings, rubber compounds and metals. Our aim is always to achieve the finest durability, hardness, friction and so on.

- Rollers in various lengths and diameters to suit all customers’ requirements.

We also offer ITR laser engraving for:

- Draw Rollers

- Embossing Rollers

- Heat Seal Rollers

- Flexographic Packaging Rollers

- Rubber Anilox Rollers

- Security Print Rollers

- Spreader/Chevron/Rewind Rollers

- Wallpaper Flexo and Surface Print Rollers

Contact one of our highly trained team today to learn more about our furnishing rollers and ITR laser engraving and how they can help your business.