NW Roller Fibreglass Sleeves Explained

- 4 July 2024

- Posted by: Scott Pendlebury

- Category: Sleeves

The industrial, lamination, and packaging sectors in the UK understand the importance of operating with the most cost-effective equipment, including fibreglass sleeves.

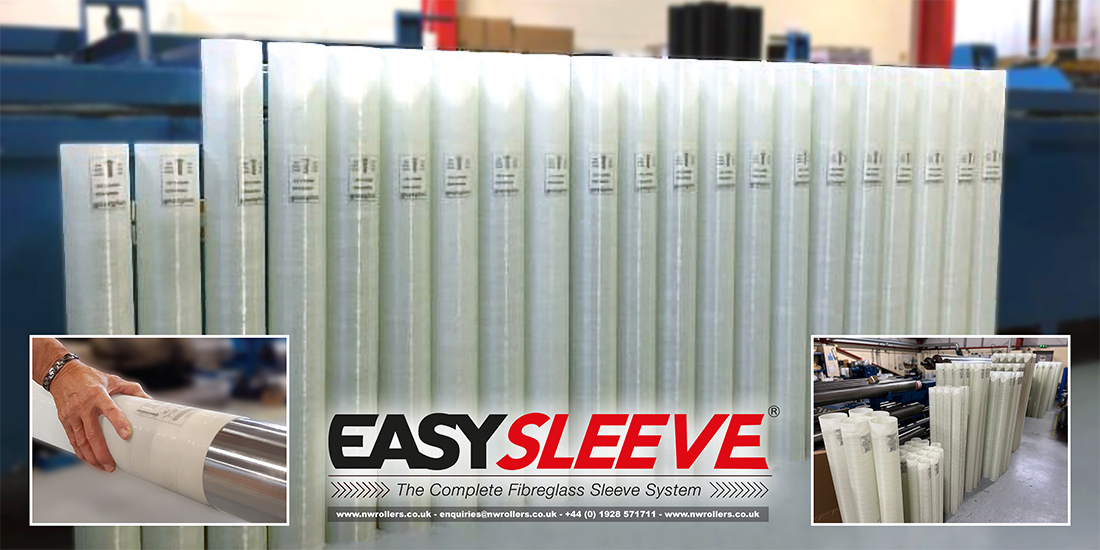

In response to our client’s needs, we developed the Easysleeve® System to supply fibreglass sleeves for the above mentioned industries.

Our extensive product knowledge and 30+ years’ experience mean we have the expertise to convert existing printing/roller lamination machines so they can utilise the fibreglass system.

The Benefits and Features of Fibreglass Sleeves

There are a range of benefits to using our fibreglass Easysleeves®. For example, they reduce:

- Costs

- Production downtime

- The need for heavy lifting equipment

- The use of specialised storage systems

- The need to use heavy-lifting crates

In addition, fibreglass sleeves can be transported easily because they have a lightweight construction.

Aside from the above, our fibreglass sleeves are:

- Suitable for a wide range of sectors because they can print a variety of products, including cement bags and facial tissues

- These sleeves come in a wide range of lengths, widths and diameters

- Conical sleeves are rubber, covered with specially developed compounds, which reduce sleeve swelling and are suitable for high solvent resistance when used with isocyanates and ethyl acetate. They are 72 mm to 360 mm in diameter and 300mm to 2500 mm in length.

- Parallel sleeves are 60mm to 400 mm in diameter and 100mm to 2500 mm in length.

- Fibreglass sleeves can be conductive (carbon-impregnated fibreglass for static dissipation)

- Fibreglass sleeves can also be non-conductive (standard glass and resin sleeves for coating, laminating and flexographic printing.

- Easy to use for fast on-off-press changeovers

- It has a 100% no-slip guarantee and won’t slip on the mandrel.

- Tough and durable

- Easy to clean

- Easy to store

Above all, our fibreglass sleeves offer consistent and reliable results.

Safety First During Our Fibreglass Sleeve Production

When we created our Easysleeve System at our site in Cheshire, our primary aim was to ensure its safety. We’re happy to report that it remains the safest tapered system available on the market worldwide.

In addition, thanks to our no-slip guarantee, the mandrels are designed and manufactured to ensure that exact specifications are met and the sleeves fit correctly. Our design ensures that sleeve loading and removal are easily achieved and the sleeves will not slip due to improper fitting.

Contact us today to learn more about our fibreglass sleeves. We’re happy to help you choose the right sleeves for your business.