Rolling Along with Innovation: North West Roller’s Cutting-Edge Solutions

- 11 January 2024

- Posted by: Scott Pendlebury

- Category: Furnishing Rollers

North West Roller Services Ltd has provided high-quality rollers, sleeves, and other consumables to printing and lamination companies worldwide since 1990. With our innovative solutions and focus on customer service, we’ve become a trusted partner for businesses seeking dependable results.

Our team of skilled technicians work in the best kind of facilities to supply products including:

- “Easysleeve” conical and parallel sleeves and sleeve systems

- Refurbished rubber-covered rollers, cylinders and sleeves

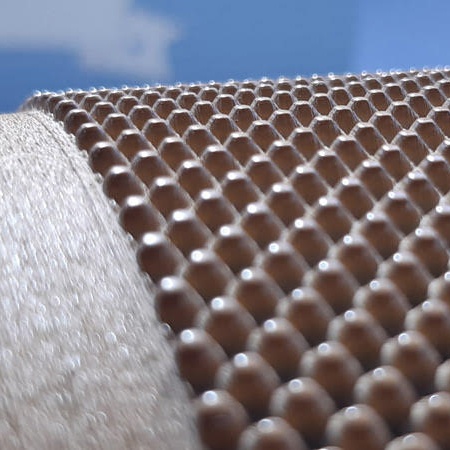

- Laser-engraved seamless ITR flexographic printing rollers

- Polyurethane (PU) rollers

- Aluminium web guide rollers

- Various other consumables

- We cater our services specifically to the furnishing rollers’ needs of flexographic and gravure printing and lamination.

Why Choose Us?

Why Choose Us?

- Over 30 years of industry experience – Our long history in this business means we understand exactly what our customers require

- Global supply and service – We export our products and services worldwide

- Innovative processes and technology – We utilise the latest equipment and techniques to manufacture superior rollers and sleeves

- High-quality standards – Every product we supply has been inspected thoroughly to ensure it meets specifications

- Customer-focused service – Our team works closely with every client to provide customised solutions

Seamless Roller Manufacturing Process

Our manufacturing process for seamless rollers involves:

- Precision engineering of aluminium cores

- Computer-controlled laser engraving for flexographic printing rollers

- Bonding using industry-leading adhesives

- Grinding and turning on CNC machining centers

- Balancing to eliminate vibrations

- Anodizing for surface protection

- Final quality control checks and measurement

This meticulous approach enables us to create rollers to meet even the most demanding requirements.

In addition to manufacturing new rollers, we also provide expert furnishing rollers refurbishment services for used rubber-covered rollers from printing presses and laminators.

Why Our Rollers Are Better

There are key reasons why our rollers consistently outperform the competition:

Superior Materials

We use top-grade metals, rubber compounds, adhesives and coatings sourced from leading global suppliers. These materials allow us to achieve better hardness, durability, friction and other properties.

Enhanced Balance

Every roller is digitally balanced to remove vibration. This allows them to rotate smoothly at high speeds for longer without the need for servicing.

Precision Manufacturing

With CNC machining and strict tolerances, our rollers are more dimensionally accurate and have superior concentricity. This directly translates to better print and lamination quality.

So contact our team today to see how we can help optimise your printing or lamination operations!