North West Roller Services Ltd are the UK market leader in conical & parallel sleeves.

North West Roller Services Ltd have manufactured both Conical and Parallel Fibreglass Sleeves for over 22 years here on our site in Cheshire. Our name has become the watchword when it comes to UK sleeve manufacture.

We supply Fibreglass sleeves covering Packaging, Lamination and Industrial sectors throughout the UK. Due to our product knowledge and technical know-how, we have the expertise to convert existing roller lamination/printing machines to utilise the sleeve system, in doing so reduce costs and decrease production downtime. Using the sleeve systems reduces the need for heavy crates, lifting equipment and specialised storage systems. Sleeves can be transported very easily due to their lightweight construction.

We are currently developing our export market providing fibreglass sleeve cores to many rubber covering and importing agencies around the world. The advantage being the rubber covering companies gain added value by rubber covering the sleeves themselves, thus becoming a local supplier within their locality.

Overview of the NWRS Easysleeve® System

The Easysleeve® System brings a whole host of benefits to gravure printing and related industries, including coating, laminating, flexography, heat transfer printing and many more.

Easysleeve Sleeves will accept ESA compounds and rubber coverings for increased repeat lengths and all types of plates including laser engraved and photopolymer.

Only the authentic Easysleeve® System offers so many benefits.

Easysleeve® is offered for the following applications

Easysleeve® System Key Features & Benefits

The World's Premier

Demountable Image Carrier

Manufactured by North West Roller Services Ltd, the Easysleeve® System continues to be the worldwide number one name in tapered sleeves.

Conical or

Parallel Sleeves.

We manufacture both conical and parallel sleeves (conductive & non-conductive) and sleeve systems, to supply the flexographic, gravure, and allied trades.

Suitable For a Wide

Range of Production

A very wide range of products are printed using Easysleeve Sleeves – everything from multi-coloured ‘top of the range’ facial tissues to

cement bags!

Easysleeve is the

Safest System

North West Roller Services Ltd created the Easysleeve System with safety in mind. The Easysleeve System is still the safest tapered system available on the market anywhere in the world

No-Slip

Guarantee

North West Roller Services Ltd are the only manufacturer confident enough to provide a NO-SLIP guarantee. A correctly fitted, genuine Easysleeve® Sleeve will not slip on the mandrel in normal use. That’s a promise

EasySleeve® Offers

Many Other Benefits

Light in weight | Easy to handle | Space-saving | Labour saving | Fast changeovers | Fast makeready | Variable repeat lengths | Consistent, reliable results | Wide range of widths & diameters | Years of proven success | Continual product development

Common questions we get asked about the Easysleeve® System

The Taper

Why a Tapered system?

Though perfectly parallel on the outside, on the inside the sleeve is tapered. This taper corresponds with absolute precision to the taper of the specially made mandrel. When correctly located on the mandrel the sleeve will be in perfect contact along its entire length and will be firmly held in place by the interference fit.

The taper makes it easier and safer to use than any other sleeve system and gives a guaranteed ‘no-slip’ performance.

- Plates | Rubber | Laser Engraved | Photopolymer

Conical and parallel sleeves are available in standard and conductive options.

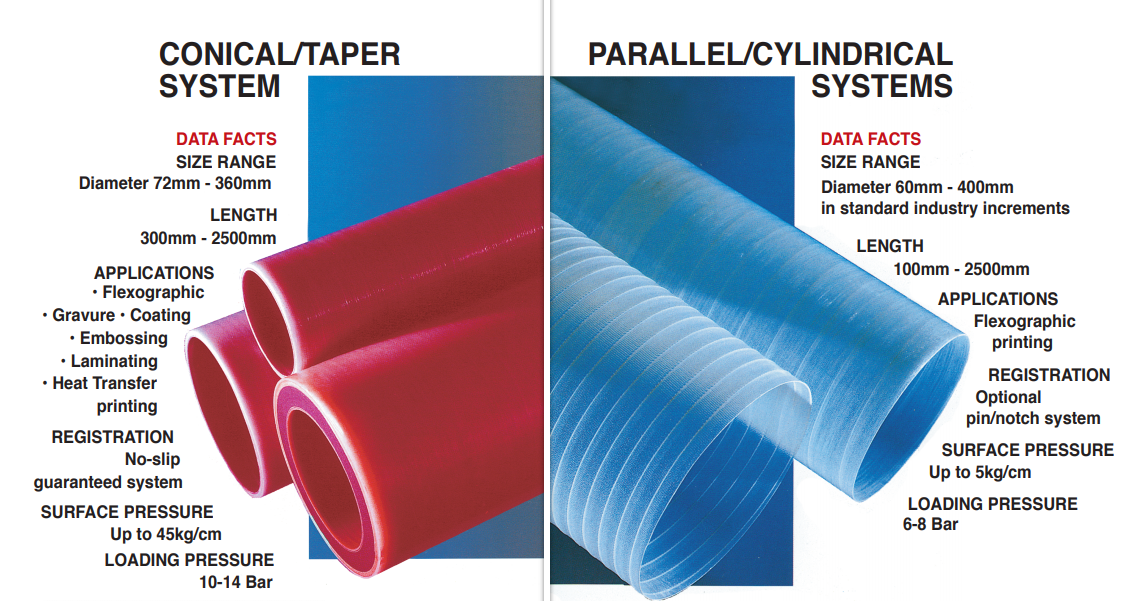

CONICAL SLEEVE

The Conical Sleeve is perfectly Parallel on the outside and the inside is Conical. This ensures a corresponding fit between the Sleeve and the Mandrel.

The Conical Sleeve has an advantage over the Parallel System as it comes with a guaranteed non-slip policy. The Sleeves are lightweight, easy to handle, safe storage with a quick change-over on press. The Conical Sleeve is supplied in two forms, conductive for the static dissipation and standard for Impression and Laser Engraving.

PARALLEL SLEEVE

Lower cost than a Conical Sleeve, optional location Notch/Pin registration to reduce slip.

The benefit over a conical sleeve is that a parallel sleeve can be cut up into different lengths and located in any position on the print mandrel for multi print across the substrate.

Parallel sleeves are supplied in two forms. Conductive for Static dissipation and Standard for Coating, Impression, and Laser Engraving.

Conical and parallel sleeves are available in standard and conductive options.

CONDUCTIVE SLEEVES

Carbon impregnated fibreglass designed for static dissipation.

In conjunction with the right compounds, these sleeves help discharge static through the rubber and the sleeve to earth

NON CONDUCTIVE

Standard construction glass and resin sleeves used for coating, laminating and flexographic printing.

These sleeves are not to be used for static dissipation but are used in conjunction with E.S.A compounds as these sleeves are insulative.

We invested in the technology to manufacture both conical and parallel sleeves and sleeve systems, to supply the flexographic, gravure, and allied trades. Rubber-covered sleeves are made compatible to industry standard dimensions.

DATA FACTS – SIZE RANGE

SOLVENT AND SOLVENTLESS LAMINATION.

Conical sleeves are rubber covered with specially developed compounds, which reduce sleeve swelling, and are suitable for high solvent resistance when used with iso cyanates and ethyl acetate.

There’s no going back on the advances made in Health and Safety at Work. Many years before the present set of stringent Health and Safety regulations North West Roller Services Ltd created the Easysleeve System with safety in mind. The original design specification was for a sleeve which would be the very safest possible. The Easysleeve System is still the safest tapered system available on the market anywhere in the world.

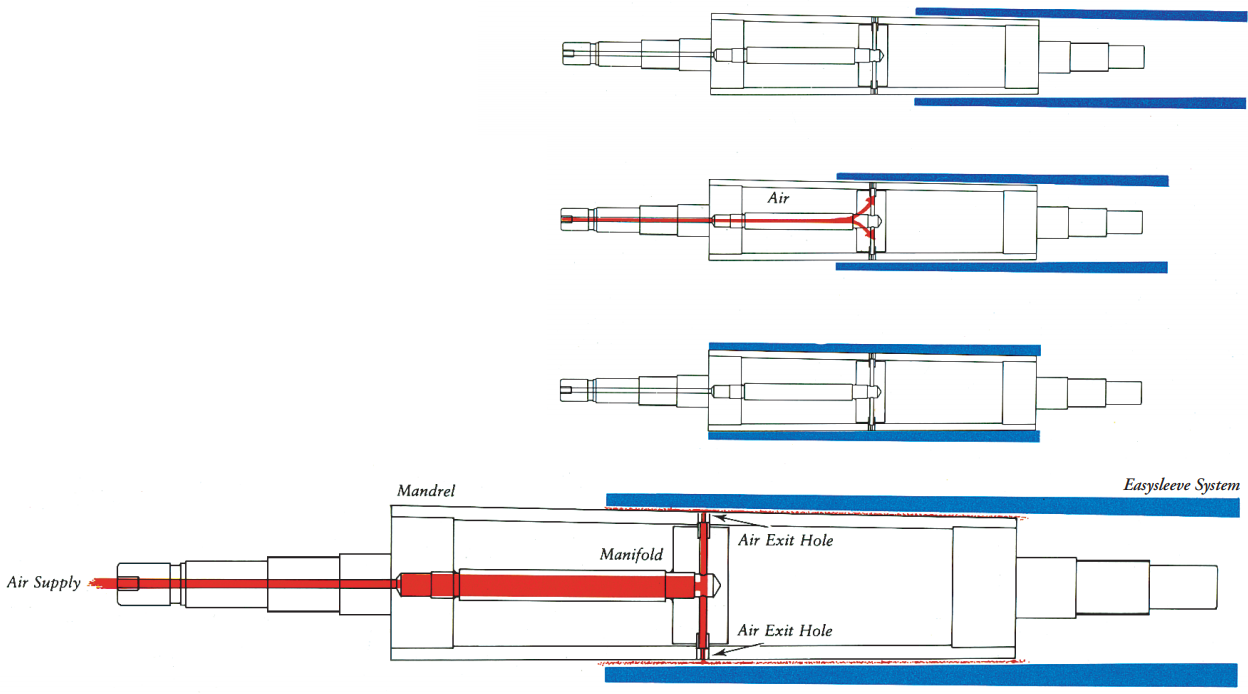

Why is it safer? Because it uses so little compressed air.

When fitting a sleeve into position only a very small amount of compressed air is needed (between 0.5 and 1.5 litres).

The mandrel’s internal manifold directs the air along the inner surface of the sleeves and not into the cavity of the mandrel. This means it is not rated as a pressure vessel and therefore is not subject to the numerous regulations required by systems using larger amounts of compressed air.